|

| Liberator advertisement from during the war. |

|

| Looks like a master die maker and his apprentice making a combustion chamber core. |

|

| Die and core for the valve area. |

|

| Die and core for a combustion chamber. |

|

| A master die maker at work. The aluminum foundry was one of the few factories to have it's own die shop "in-house". |

|

| This looks like one of the early test molds because of the crude way they are doing it. This could even be at factory #70 where the training took place early in 1942. |

|

| These wires were what kept the delicate cooling fins made of sand from collapsing during the molding process. After all the wires were in place, the rest of the mold was filled until it was flush. |

|

| The workers became very fast at inserting all the hundreds of wires for each mold. |

|

| Putting a finished mold together. |

|

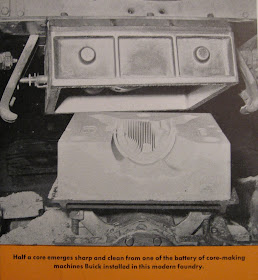

| Compressing a new core. You always needed the other half of the mold. |

|

| Compressing a new core. |

|

| Making the new cores. |

|

| Making the cores before baking in the special ovens. |

|

| Just as any other casting, there was usually more than one part needed to make up the cavities. |

|

| Working on a special inner core. It took a lot of trial and error to get things right. |

|

| Inner cores made up. |

|

| Making a mix. Aluminum scrap could only be re-melted a few times before it was as brittle as glass when cured. |

|

| Slag removal. |

|

| Making ingots. |

|

| Making the aluminum ingots, so you had a precise amount ready for each pour. |

|

| Freshly made molds will be lined up for easy pouring. |

|

| Freshly poured. |

|

| Making a pour. |

|

| Making a pour. |

|

Filling another ladle.

|

|

| Filling another ladle. |

|

| The pouring of aluminum was a very precise operation. It had to be just the right temperature and consistency. It poured like syrup which was nothing like pouring iron. |

|

| This is where the ladle was placed between pours. |

|

| Opening another mold. |

|

| I think this was called the "Blast Machine" and was used for checking the new casting for defects and also cleaning out. |

|

| Reclaiming core sand entered here. The steel wires used for supporting the delicate cooling fins made of sand were separated by magnets. |

|

| A band-saw makes quick work of removing much unwanted material |

|

| A band-saw makes quick work of removing much unwanted material. |

|

| A band-saw makes quick work of removing much unwanted material. |

|

| A band-saw makes quick work of removing much unwanted material. |

|

| Fine grinding the base of the head. |

|

| Heads entering the heat treating oven. |

|

| Air aging area. I tried to figure out the procedure here, but I'm still not sure. |

|

| One of many air aging turntables. |

|

| Loaded on the turntable for age curing. |

|

| Either ready for the air aging area or already done. |

|

| After all curing is done they are on the way to the finish and cleaning area. |

|

| Automated milling machines. |

|

| Automated milling machines. |

|

| Automated milling machines. |

|

| Not sure of this one yet. |

|

| Not sure of this one yet. |

|

| May be the "Jolt Squeeze machine". |

|

| May be the "Jolt Squeeze machine". |

|

| Buffing the heads. |

|

| The tools needed for the finish work. |

|

| Finish work. |

|

| Hand work with a hand saw. |

|

| Hand finishing with grinders and other tools. |

|

| Hand working with grinders and other tools. |

|

| Hand working with grinders and other tools. |

|

| Hand working with grinders and other tools. |

|

| Cleaning station. |

|

| Cleaning station. |

|

| Automatic packer for the heads. |

|

| Heads ready for the trip to the Buick assembly plant in Melrose Park Illinois. |

follow the links:

No comments:

Post a Comment