|

| The synchcromesh transmission housing being machined. You can see many cases in the background. I only have this one photo showing the manual transmission for the M-4. I'm thinking this work was being done in another factory other than #02 at Buick, probably #31 or #66. |

|

| A footing for a machine at factory #02. |

|

| This shows the conversion from automobile shipping to tank drive assembly. These are the footings going in for machines in the east annex of factory #02. Parts of some machines are already in place. |

|

| This still shot (from a Leonard Thygesen documentary film) shows the layout of factory #02, as described in the following photos taken during World War II at Buick. |

|

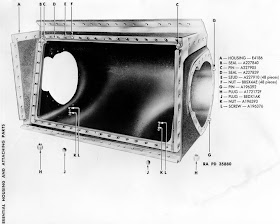

| A diagram of the cast differential housing of the M-4 medium tank. Nicknamed the "Sherman". From the cast in markings these came from different foundry's near Chicago. You can look them up in the "Sherman Minutia" link. |

|

| A finished housing. |

|

| Milling machine. Looks like all mill and drill work took place in the east annex of factory #02. |

|

| Loading a multiple drilling machine. |

|

| Loading a multiple drilling machine. |

|

| Loading a multiple drilling machine. |

|

| There are many of these photos, so I will post a few. |

|

| A large automated milling machine in the east annex of factory #02. |

|

| A large automated milling machine in the east annex of factory #02. |

|

| Mill work being performed on the armored cast differential housing. |

|

| Mill work in the east annex of factory #02. |

|

| Hand grinding. |

|

| Looking north in the east annex of factory #02. A lot of automobiles were loaded onto boxcars from this area before World War II. |

|

| Some finish work. |

|

| This would be the west side of factory #02 in the assembly area. You are facing east. |

|

| Mill work in the east annex of factory #02. |

|

| Multiple drilling operation. |

|

| Multiple drilling operation. |

|

| Mill work. |

|

| A single drilling operation. |

|

| The armored cast differential housing having the alignment pins installed. |

|

| This is the east annex of factory #02. |

|

| A multiple drilling machine. |

|

| The armored cast differential housing being machined. This appears to be where one of the two alignment pins will be installed. Two on each side for the final Drive installation. |

|

| The armored cast housing being machined. |

|

| Differential carriers ready for machining. These came from the same foundries near Chicago as the differential housing. "Sherman Minutia" Looking west in the factory #02 train shed. |

|

| Differential carrier machining. |

|

| Differential carrier machining. |

|

| Differential carrier machining. |

|

| Differential carrier machining. |

|

| Differential machining. One of many multiple drilling machines. |

|

| Differential carrier machining. I believe this is the same operation shown farther below, only from a different perspective. |

|

| Differential carrier machining. |

|

| Differential carrier machining.This actually shows a large lathe table cutting a perfect mating surface for the transmission. |

|

| Differential carrier machining. A multiple drilling machine saved many hours of work. |

|

| Differential carrier machining. This multiple drilling machine photo has been shown in many Buick publications. |

|

| Differential carrier machining. |

|

| Differential carrier partial assembly. |

|

| Heat treating on a differential gear. I see bevel and straight gears shown hear. This would most likely be in factory #38 heat treat. |

Michigan Motor Casting Company

|

| Diagram of the final drive housing. |

|

| Final drive housing machining. |

|

| Final drive housing machining. |

|

| Final drive assembly. |

|

| Here a right hand final drive is being installed. |

|

| Final drive housing machining. |

|

| Final drive housing machining. |

|

| Final drive housing machining. |

|

| This diagram shows the parts of the final drive for the tank track. |

|

| A sleeve being press fitted on an axle. |

|

| Final drive hearing bone gear being machined. I'm not sure yet of the factory doing this work. |

|

| Brake drum machining. |

|

| Machine work on the brake shoe. |

|

| This is the brake lining being installed. |

|

| Facing south in the train shed. Looks like maybe tool repair going on but I'm not sure. |

|

| Here a part is heated before placement, then cooling shrinks the part for a tight fit on the differential housing. We are obviously facing north in the train shed #02. The reinforced concrete annex was on the west side of the train shed and a smaller annex (old car shipping area) on the east side. Boxcars were lined up here in the past. I took a photo here in 1997 in (almost) the same spot with the identical direction. |

|

| Heat shrinking (heated then cooled) for placement on a differential part. This is facing west, at the north-end of the (larger) main train shed of factory #02. |

|

| Inserted differential ready for testing. |

|

| Testing a finished differential. |

|

| Assembly on the M-4 differential. |

|

| Assembly on the M-4 differential. |

|

| A finished differential. |

|

| Inserting a differential. |

|

| Only the differential in place. |

|

| This is the differential splash-pan partially visible below. |

|

| Here is the finished differential with the right and left brake drive units all in place. |

|

| The transmission on the left with the differential housing on the right. This is the operation being performed below. |

|

| Here the transmission is being mated with the differential carrier, before that complete unit mates with the armored outer housing. |

|

| This is a cutaway of the M-4 power train. This gives a great view of the differential assembly and you can also see the brake bands used for steering the tank. |

|

| Here is final drive assembly. |

|

| Here we see the left hand final drive already installed, with the left one in process. |

|

| Final assembly of the M-4 power train. |

|

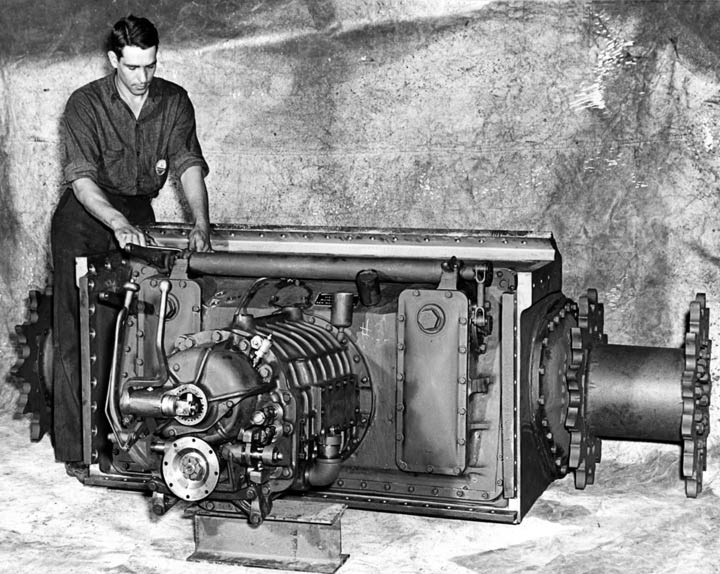

| Here we see the manual transmission (synchcromesh). of a finished unit. |

|

| This view (facing south-east in the old train shed #02) shows a finished assembly ready for shipping to the assembly plants. |

|

| This view (facing south in the old train shed #02) shows a finished assembly ready for shipping to the assembly plants. |

|

| This view (facing south in the old train shed #02) shows a finished assembly ready for shipping to the assembly plants. |

|

| This view (facing south in the old train shed #02) shows a finished assembly ready for shipping to the assembly plants. |

|

| Here is the finished transmission and differential drive unit being installed at the factory in Grand Blanc, Michigan just south of Flint. SHERMAN MINUTIA |

No comments:

Post a Comment