|

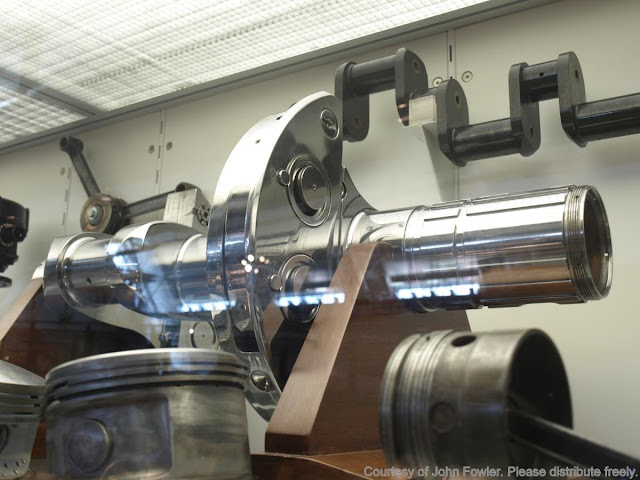

| Besides the reflection, this is a good view of the liberator crankshaft. On the wall in the rear is a Liberty crankshaft from World War I which Buick also made. |

|

| Here we see a fully assembled crankshaft undergoing the fine balance that was required, so as not to have the engine tear itself apart from torsional vibration. |

|

| A lot of inspection took place on every part of the Liberator engine. In this photo we see (at left) the crankshaft and (at right) the prop-shaft. |

|

| This worker is loading a crankshaft with a powered lift because they are very heavy. This crank does not have the splines cut in yet. |

|

| This worker is cleaning out an oil gallery on a journal. I read somewhere that they did this with vinegar. |

|

| Notice all the micrometers and dial gauges, this is another inspection area. |

|

| Here is another worker performing the (by hand) balancing of the crankshaft throws. |

|

| Here we can see on the crankshaft throw (at the left) that the dynamic damper and (damping) counterweights are now installed. |

|

| I think we are seeing the first step in determining the counterweights that will be installed. |

|

| I think this is just another (of many) inspection stations. The counterweights or dynamic damper has not been installed yet. |

|

| This actually looks like lathe work being performed on the vertical side of the crankshaft throw. |

|

| I'm thinking that this machine was used for straightening the crankshaft after all the various machining operations. |

|

| This may show the final grinding or polishing on the crankshaft throws. |

|

| Rough grinding on the vertical surface of the crankshaft throws. |

|

| This and the photo above I believe shows the final milling on the horizontal surface of the crankshaft throws. |

|

|

| This looks like the first rough grinding on the journals. |

|

| First milling being done on the crankshaft. |

|

| Here is a fully machined crankshaft before final assembly |

|

| This photo I took at the Sloan museum in Flint, Michigan shows the location that the crankshaft will assume in the "POWER SECTION" of a Liberator engine. |

|

| Heat treat furnaces. |

|

| First the heat treating in these large furnaces and then the raw forgings head for plant #31 |

|

| Here is the raw forging after the hammer has done it's work. |

|

| Checking the billets. |

No comments:

Post a Comment